Innovative Andrews Automation’s chain conveyors improve productivity for pharmaceutical manufacturer with toxic process

Andrews Automation designed, manufactured and installed a custom made conveyor system for a pharmaceutical manufacturer who use the highly toxic Ethylene Oxide in their manufacturing process.

The manufacturer provide sterilised solutions to the pharmaceutical and medical sectors and at the end of the manufacturing process need to move the solutions from a highly toxic de-gassing chamber to the warehouse for storage before dispatch.

They needed the help of Andrews Automation to automate this, ensuring safety at all times and making it as efficient and effective as possible.

Andrews Automation provided a unique and bespoke solution

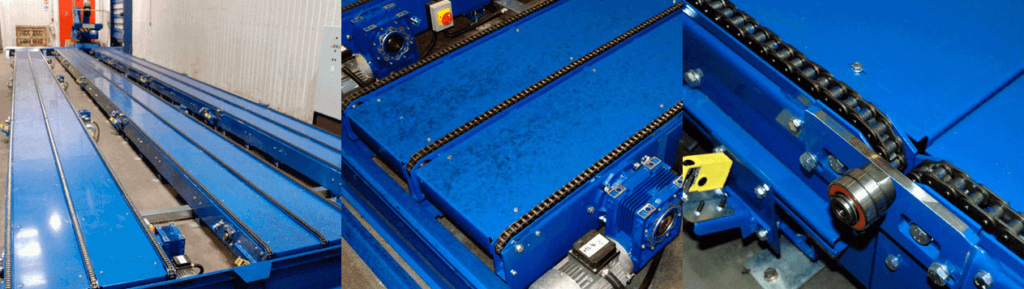

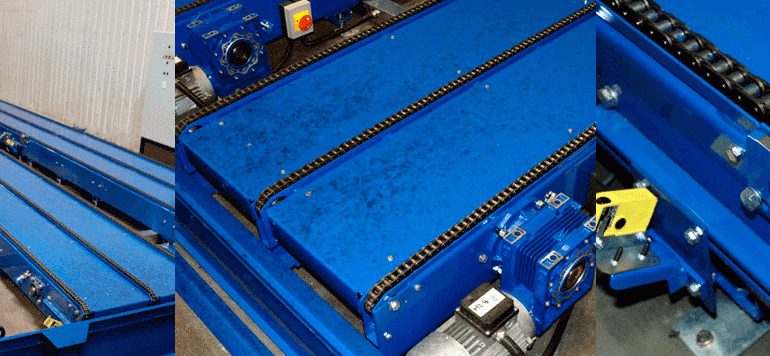

Using our twin strand chain conveyors we built 3 identical parallel conveyor lanes each capable of holding up to 16 Euro pallets to a weight of 1500kgs – Only an AGV could be used.

It unloads pallets from the degassing chamber directly on to the conveyor accumulating them in batches. Then the 4 powered sections transport the pallets to a forklift truck off-loading station.

This allows warehouse staff to work more efficiently and unload pallets when it is most efficient to do so, in batches.

An innovative solution that improves productivity

We were able to provide a very effective, efficient and innovative pallet conveyor system working in what is a sensitive and highly controlled environment that really helped us to improve productivity.

Full compliance is our guarantee

It goes without saying that everything we do is Health and Safety compliant, whether working in a sensitive environment or not. We guarantee it.