Belt conveyors for UK components manufacturer

This particular client is a global player in the manufacture of automotive components. They had a requirement to transport consignments from a mezzanine floor in a much quicker timescale that was previously happening.

Our in-house technical team then began work on designing a system for client approval. Once a solution was agreed we began the manufacture and in-house build of the system in preparation for our installation team to visit site and put the new belt conveyor system in. Andrews Automation came up with the solution of utilising a twin belt conveyor system. The agreed system compromised of a combination of decline belt conveyors, which in turn links to both 24VDC powered and non-powered accumulation roller conveyors.

Upon installation and successful commissioning, our client now had a conveyor system that allowed them to move far larger quantities of stock on different levels safely using the belt conveyors. The basic idea of the system was that plastic totes were fed into the system with one conveyor handling incomplete parts orders, with the other belt looking after completed orders.

As with all our custom-made conveyor systems, we offered a solution which was flexible, efficient and competitively-priced. This was backed up by our after sales support and maintenance service.

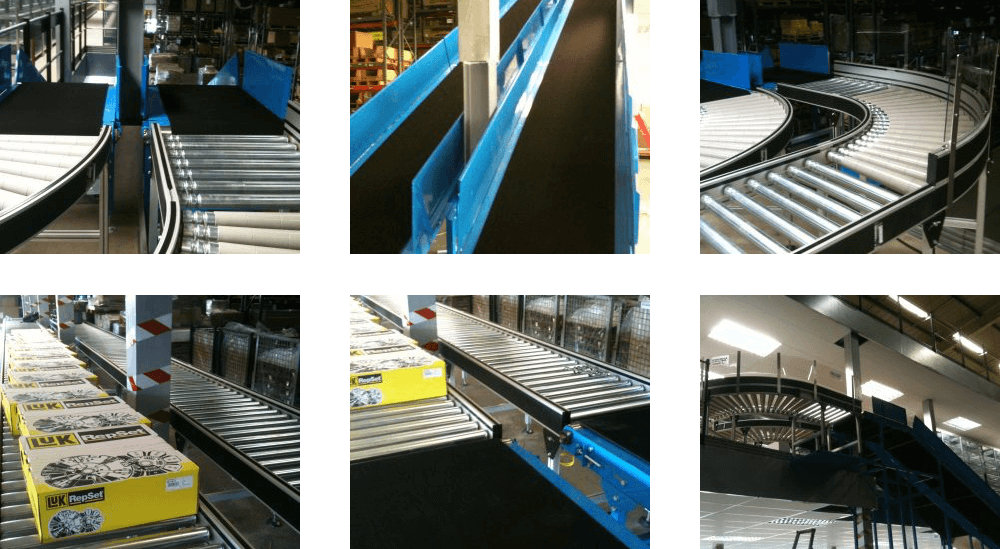

Below are a few images of the belt conveyors in action, showing client parts being transported from a mezzanine floor on a declined conveyor, and then moving onto a non-powered roller conveyor system prior to packing and transportation.