Integrated conveyor systems are a speciality for Andrews Automation Ltd. This is how we stand out from the crowd against our competitors. Many conveyor suppliers out there purely concentrate on the provision of conveyor hardware only, whether that be belt conveyors, roller conveyors, chain conveyors etc.

Andrews Automation Ltd are able to design and manufacture complete conveyor systems for materials handling from start to finish. Our conveyor systems can be designed with any number of the following value added products integrated into the solution:

- Pallet wrapping solutions

- Strapping machines – vertical and horizontal

- Pallet lifts or lift tables

- Turntables

- Cross-transfer (chain or belt transfer) solutions

- Transfer car / trolley

- Automated / robot palletising

- Pallet dispensers

- Pallet inverters

- Sortation systems

- Barcode reading

- Labelling solutions

- ‘Bag-in-a box’ technology

Our conveyor systems are designed by our design engineers in-house, where we also build and functionally test all of our solutions.

We design all mechanical and control elements of our conveyor systems giving us greater control in designing the right system for the clients application. Safety systems including fencing, emergency stops, light guarding, system interlocks, warning signals etc. are key to our designs. Full system training can be arranged for any number of operational staff.

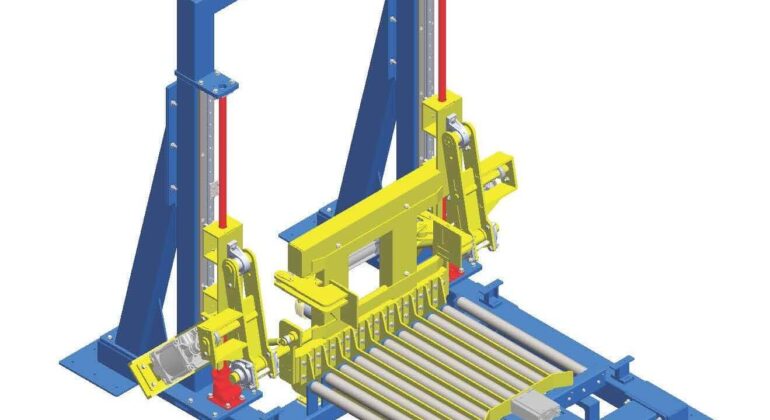

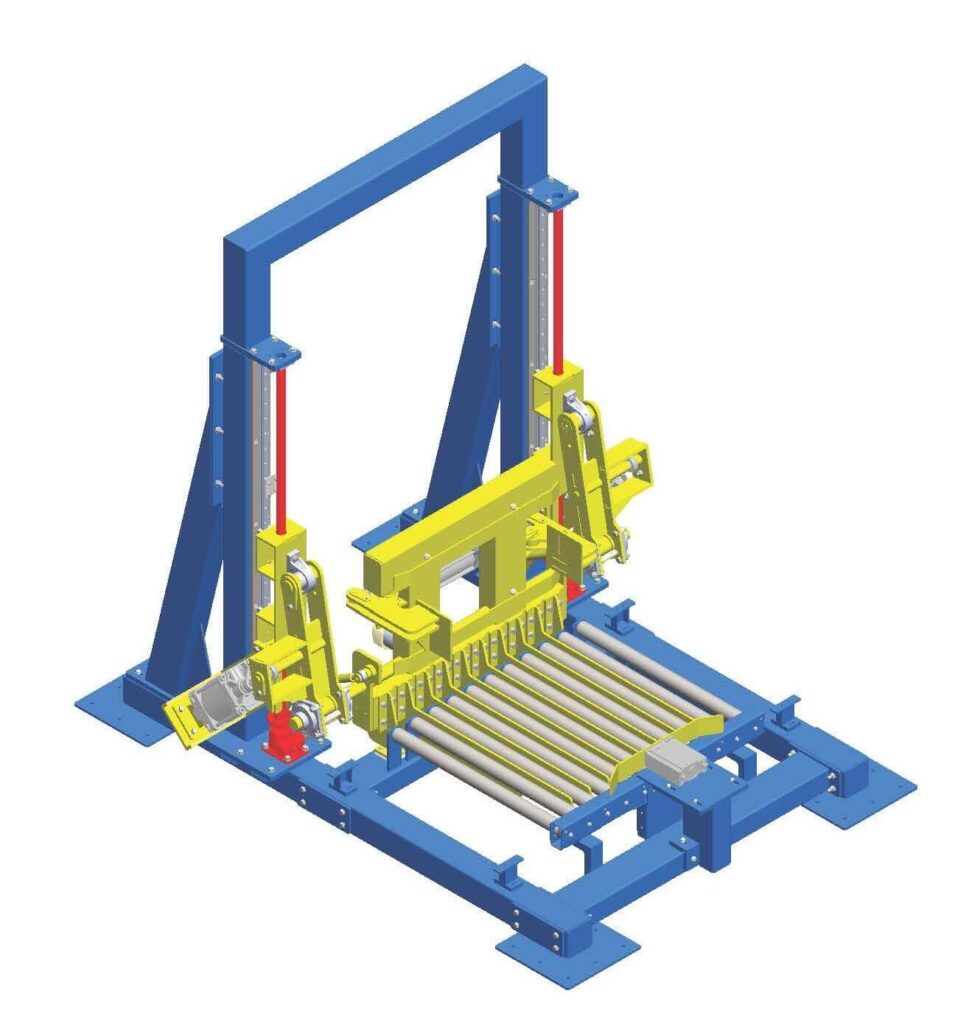

Throughout February and March 2018, we set to work on building a tipping system capable of emptying a magnum pallet with up to 1000kg of contents onto a series of conveyors in preparation for sorting and processing.

The images below show the system design, as well as the early stages of manufacture and testing:

For more information on how conveyor systems from Andrews Automation Ltd can improve your business, please call the office today on 01405 768900 or email support@andrewsautomation.com