Robot Palletising Systems

There are many benefits to investing in robot palletisers. Clients have reported significant increases in palletising KPI’s including improvement in throughput and stack stability. They are also reporting constant and reliable ‘pallets-per-hour’ figures throughout the day, every day of the working week. It goes without saying that our robot palletisers do not require breaks, do not fatigue during the course of the day, and will not contribute to any absenteeism or potentially costly RSI injury claims

We are able to supply vacuum head systems, ideal for solutions where a number of different sized products are handled, as well as systems with bespoke gripper heads for those items that are tricky to handle such as distribution tote bins. Whatever your requirements, our aim is to supply you with a cost-effective and reliable palletising solution that is operator friendly and safe.

Andrews Automation Ltd’s solutions are designed around your existing operational structures and processes. The safety of your workforce is paramount. Andrews Automation provide secure fencing systems that surround the robot cell, and supply sensor curtains, a series of light guards detecting movement and motion at relevant entrances and exits. If anyone were to enter the robot cell, the system would instantly shutdown.

Ideal for solutions where a number of different sized products are handled

Design flexibility based on operational requirements.

Cost-effective and reliable palletising solution

Andrews Automation Ltd’s solutions are designed around your existing operational structures and processes. The safety of your workforce is paramount. Andrews Automation provide secure fencing systems that surround the robot cell, and supply sensor curtains, a series of light guards detecting movement and motion at relevant entrances and exits. If anyone were to enter the robot cell, the system would instantly shutdown.

Robotic palletising solutions vastly improve industry productivity. Robots work harder, longer, and in a lot of cases faster than manual processes. Robotic systems can work up to 24 hours a day, for 7 days a week, without any reduction in performance. It also goes without saying that they require supervision or breaks, and are not prone to regular absenteeism. Andrews Automation solutions do all the heavy lifting for you, enabling your workforce to be free to spend their time on tasks that require thought and human judgement. The result is a system that maximises efficiency and improves site health and safety.

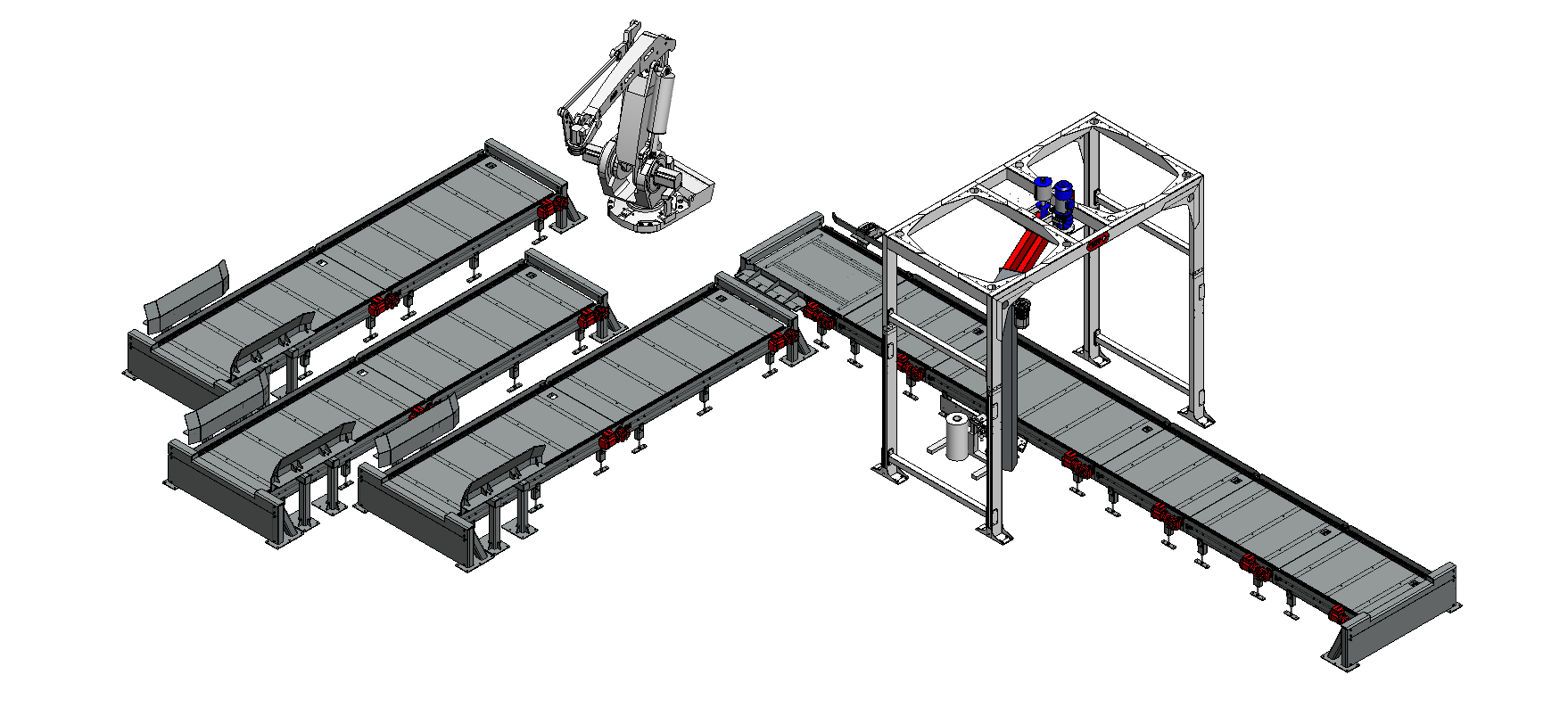

Andrews Automation Ltd specialise in complete integrated systems. We can include pallet decanting options to automate the system even further, even develop bespoke robot gripper heads to physically pick up a pallet and place it in the palletising area prior to product palletisation. We can provide automated in-feed conveyors, indexing and queuing product prior to entry into the robot cell. Once the palletising process has finished, we can also supply automated conveyor options to transport stacked pallets out of the pallet cell, ready for safe FLT collection and distribution.

We are your trusted engineering partner

Andrews Automation Ltd are able to offer an in-house design service with the facility to design Robot Palletising Systems to suit your needs

AAL are able to offer a reliable, long-term solution based on the client product to be transported.

Request our Brochure

Request our brochure today to receive all the latest news, career opportunities, videos and much more…